Hydraulic jacks are essential tools in various industries, providing the necessary lifting power for heavy machinery and equipment. However, like any mechanical device, they can encounter problems that affect their performance and safety. This guide will help you identify common hydraulic jack problems and solutions, as well as provide tips for effective jack maintenance and repair strategies.

Common Hydraulic Jack Problems and Solutions

Understanding the typical issues that can affect your hydraulic jack is crucial for maintaining its functionality and ensuring facility safety. Below are the most common problems you may encounter, along with their solutions:

Slow Release or Extension Issues

If you notice that your hydraulic jack is not lifting or releasing as quickly as it should, it may indicate a problem with the hydraulic fluid or internal components. Common causes include low hydraulic fluid levels, air trapped in the hydraulic system, and worn seals or valves. To resolve these issues:

- Check the hydraulic fluid level and replenish if necessary.

- Bleed the system to remove any air bubbles that may be causing slow operation.

- Inspect seals and valves for wear, replacing them as needed during jack maintenance to ensure smooth operation.

Oil Leak or Foaming Oil

Oil leaks can significantly impair your jack’s performance and pose safety risks. If you notice foaming oil, it could be a sign of air in the system or contamination. To address these issues:

- Identify and repair any sources of leaks immediately.

- Replace damaged seals or O-rings to prevent further leakage.

- Flush the system and refill it with clean hydraulic fluid to maintain optimal performance.

Restricted Wheel Movement

Restricted wheel movement can hinder your floor jack’s maneuverability, making it difficult to position under loads. This issue is often caused by debris accumulation, lack of lubrication, and damaged wheels or bearings. To fix this problem:

- Regularly clean the wheels and axles to remove dirt and debris.

- Lubricate all moving parts according to manufacturer recommendations.

- Replace any damaged wheels or bearings to restore full functionality.

Damaged or Worn Seal

Seals are critical for maintaining pressure in your hydraulic jack. When they become damaged or worn, they can lead to leaks and reduced lifting capacity Here’s how to address this issue:

- Regularly inspect seals for signs of wear or damage during your jack maintenance checks.

- Replace worn seals promptly to avoid further complications.

- Ensure proper installation of new seals to maintain hydraulic integrity.

The Importance of Regular Maintenance

Regular hydraulic jack maintenance is essential for ensuring its safety, efficiency, and longevity. By prioritizing jack maintenance, you not only help prevent costly breakdowns but also extend the life of this valuable equipment. A well-maintained jack operates more safely and efficiently, reducing the risk of team accidents and improving overall productivity.

Daily Maintenance

Make it a habit to conduct these daily checks on your hydraulic jack:

- Perform visual inspections for any signs of damage or wear.

- Check for oil leaks or changes in fluid levels.

- Ensure all moving parts are clean and free from debris.

Monthly Maintenance

Take time each month to conduct more thorough maintenance:

- Lubricate all moving parts according to manufacturer specifications.

- Clean air vents to prevent contamination from dust and debris.

- Tighten any loose bolts or fittings to ensure stability during use.

Annual Maintenance

Schedule an annual jack maint enance check to keep your equipment in top condition:

enance check to keep your equipment in top condition:

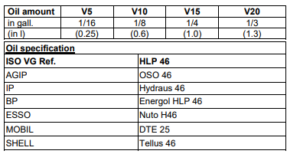

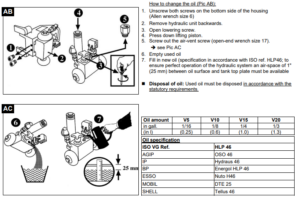

- Perform a complete oil change using manufacturer-recommended hydraulic fluid.

- Conduct a thorough inspection of all components for wear and tear.

- Test the jack’s lifting capacity and overall functionality.

Get Professional Guidance from Hydraulic Experts

While many hydraulic jack problems and solutions can be addressed through regular maintenance and basic repairs, some issues require expert help. If you find that your hydraulic jack is not working despite your best troubleshooting efforts, it’s important to seek professional assistance.

At GKS Moving & Lifting Solutions, we offer expert guidance for all your hydraulic jack repairs and maintenance needs. Our specialists provide comprehensive support for jacks and other moving and lifting solutions, including access to manufacturer manuals for troubleshooting common issues. Don’t let equipment failures compromise your operations or safety. Contact us today to get the professional guidance you need to ensure your hydraulic jacks perform at their best!