Frequently Asked Questions

Don’t see your question below? Contact us – we’ll respond promptly with all the information you need.

Jacks

What kind of toe jack should I get?

When should I use an external pump with my GKS toe jack?

What types of pumps can I use with my jack?

How do I maintain my jack to keep it in great shape?

- Grease the slides and lifting piston periodically

- Clean the air-vent screw with compressed air

- Change the oil in the jack at least yearly

See page 8 of our toe jack operating manual for more advice on maintaining your hydraulic toe jack.

What are other best practices concerning the GKS hydraulic toe jack?

- Do not overload the toe jack. Using the toe jack beyond its stated capacity will either reduce the usable life of the jack or cause a failure.

- Do not lay the toe jack on its side. This will cause oil to get into the air vent screw, causing an issue when you try to operate the jack.

- Keep the toe jack in a relatively clean, dry place. This will prevent clogging and rusting of the toe jack.

Where should I take my jack to get it repaired?

My jack isn’t working, what should I do?

Where are the jacks made?

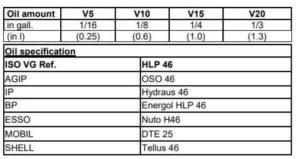

What type of hydraulic oil do GKS jacks use?

Why does the V20 have 2 actuators?

Why do the feet swivel on a GKS toe jack?

Once the machine is lifted enough to put blocks or cribbing underneath, block the load and then point the feet of the jack towards the load again.

Once the machine is lifted enough to put blocks or cribbing underneath, block the load and then point the feet of the jack towards the load again.  Do not keep the feet of the jack pointed parallel to the load for the entire lifting operation, as this might bend the toes or cause a lifting operation failure.

Do not keep the feet of the jack pointed parallel to the load for the entire lifting operation, as this might bend the toes or cause a lifting operation failure. Why is our toe made of forged steel instead of cast steel?

In short, forged steel is stronger and will bend instead of break when overloaded. Most other toe jacks are made of cast steel, a cheaper but weaker manufacturing method. Click here to get more information on the difference between forged and cast steel.

Why do our jacks costs more?

- Our toe jacks are made in Germany

- Every jack comes with a test certificate and are ASME/ANSI complaint.

- The toes on our jacks are made of forged steel, stronger than the industry standard of cast steel.

- The toe on our jack is adjustable, meaning less blocking of the load.

- There are wheels on our jack so that transport is a breeze.

- You can operate the toe jack both manually and with an external pump.

- The same capacity is present on the toe and the head of the jack.

- The feet on the toe jack swivel, enabling lifting from a lower loading height.

Where can I get spare parts from?

Industrial Dollies

When should I use a 3 versus a 4 point system?

What condition does the floor have to be in in order to employ GKS skates?

What adhesive to do you use to glue on the rubber pads onto the dollies?

Where are the dollies made?

Will the industrial dollies mark up my floor?

What is the advantage of using a rotating dolly/transport dolly/container dolly?

How much force to you need to pull something at start, and then to keep it moving?

How do I lift the load to get the dollies underneath of it?

- You can use our GKS hydraulic toe jacks that easily go under machines to lift them.

- You can use a crane to lift and place the load onto the dollies.

- You can use a forklift to prop up the load and scoot the dollies underneath.

Robots

What is the warranty on the ROBOT?

How long is the battery life on the GKS ROBOT?

Can I operate 2 GKS ROBOTS at the same time?

What does the repair procedure look like?

What does maintenance on the ROBOT entail?

Do you offer training on the GKS ROBOT?

We do not typically offer training on the GKS ROBOT because it is super easy to use! See this brief video to get a basic understanding of how to operate the ROBOT.

How many GKS ROBOTS are in the field?

Do you stock on replacement parts here in the US?

How long do the batteries typically operate for?

What powers the remote control?

Can the ROBOT serve as a tugger unit?

How fast does the ROBOT go?

How long does it take to charge a ROBOT battery?

Does the ROBOT have a lifting table to raise the load?

The standard ROBOT units do not have a lift table, but we do offer this feature as a made to order option. Take a look at our ROBOT 40 Liftup video to see a practical demonstration of the lift table in action.

How do I lift the load to get the ROBOT underneath of it?

- You can use our GKS hydraulic toe jacks that easily go under machines to lift them. We even offer a high stroke toe jack to reduce the need for blocking.

- You can use a crane to lift and place the load onto the dollies.

- You can use a forklift to prop up the load and scoot the dollies underneath.